In today’s fast-paced world of electronics manufacturing, ensuring the quality and reliability of printed circuit board assemblies (PCBAs) is paramount. This article explores the significance of PCBA testing in quality assurance processes, highlighting how Maker-ray, a leading brand in the industry, has revolutionized PCBA testing with their innovative solutions.

The Importance of PCBA Test in Quality Assurance

PCBA testing plays a critical role in verifying the functionality, performance, and reliability of electronic products. By subjecting PCBAs to rigorous testing procedures, manufacturers can identify defects, faults, or errors that may impact the overall product’s performance or longevity. A comprehensive PCBA test helps ensure that only high-quality and reliable PCBAs make it into the final products.

Benefits of PCBA Testing

Defect Detection: PCBA testing enables the early detection of defects, such as faulty components, soldering issues, or electrical connectivity problems. Identifying these issues at an early stage helps prevent defective products from entering the market.

Cost Savings: Investing in PCBA testing upfront can help save considerable costs in the long run. By identifying and rectifying defects early on, manufacturers can minimize rework, warranty claims, and product recalls that are usually associated with subpar PCBAs.

Maker-ray’s Innovative PCBA Testing Solutions

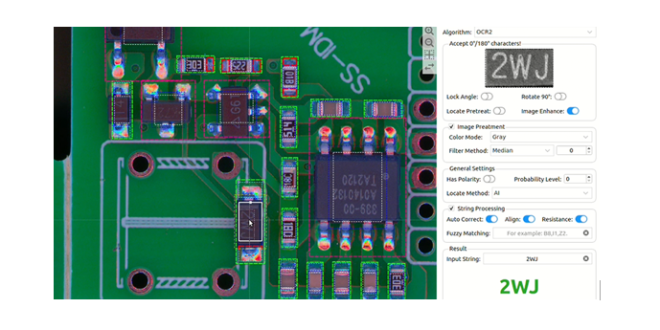

Advanced Testing Equipment: Maker-ray provides a wide range of advanced testing equipment and tools designed specifically for PCBA testing. Their solutions include automated optical inspection (AOI) systems, in-circuit testers (ICT), and functional testers that enable comprehensive testing of PCBAs at various stages of production.

Accuracy and Efficiency: Maker-ray’s solutions are known for their accuracy and efficiency, ensuring reliable test results while minimizing false positives or negatives. These solutions leverage sophisticated algorithms and intuitive user interfaces to streamline the testing process and optimize productivity.

Conclusion

PCBA testing is a crucial aspect of quality assurance in the electronics manufacturing industry. By investing in innovative PCBA testing solutions like those offered by Maker-ray, manufacturers can enhance product reliability, minimize defects, and improve customer satisfaction. With advanced technologies, accuracy, and customizability, Maker-ray continues to be a trusted brand for PCBA testing solutions, empowering manufacturers to deliver high-quality electronic products to the market.

Jobsearchdone.com Top News Share Website

Jobsearchdone.com Top News Share Website